ashamvcucmaf's Blog

When it comes to solar panel quality inspections what are the factors that influence the outcome and how do they interact with one another

The photovoltaic cells are only one component of a solar panel, which is composed of a number of other photovoltaic cells, each of which is different in size (depending on the number of cells required to convert sunlight into electrical energy), and is composed of several photovoltaic cells in addition to the photovoltaic cells. As a result of the requirement for precise power conversion, it is necessary to maintain control throughout the manufacturing process, both before and during the actual manufacturing process.

Prior to the start of production, there is a stage known as pre-production that occurs

Before the actual manufacturing process can begin, a number of steps must be completed, including the pre-selection of the cells that will be integrated into the final solar panel, verification of the glass control process for mechanical resistance and transparency control, verification of the lamination time, and confirmation of the various stages of control that will be implemented throughout the production process.

It is customary to celebrate the completion of a production after it has been completed

After the solar panel has been fully assembled, manufacturers should conduct Pre-Shipment Inspections (PSI), according to ProQC, in order to ensure that the final product is of high quality inspection services and meets customer specifications.

During the final Container Loading Supervision control inspection process, a large number of different components of the entire solar panel are inspected in detail. An end-to-end verification checklist is provided below that should be used as a guideline throughout the process:

First and foremost, a visual examination must be carried out

Cosmetic and sanitary condition of the product – the overall appearance and cleanliness of the product

During the visual inspection process, each system is checked for overall aesthetic appeal. This includes checking that all of the components (solar panels, batteries, inverters, solar chargers, cables, and other accessories) are in good working order. Scratches, dents, and dirt are all examples of damage or deformation that need to be avoided at all costs on each of these items.

Ensure that the sealant around the edges of the solar panels is tight and that it is properly adhered to the panels by visually inspecting them.

Verify that nothing is broken, that there are no cracks in the solar panel laminate, that there is no damage to the frame, that all of the fixing/installation holes, drain and grounding holes, junction box, and anything else specified in the product specifications are present, and that the product complies with all of the specifications.

Inspect the various components to ensure that the correct branding and origin are present, which may include the following: glass, tedlar, aluminum frame; cells; junction box; cables; MC4 connector; inverters; solar chargers and batteries, among other things.

2. The accuracy of the dimensions is checked:

Size is expressed as a combination of length, width, and thickness.

A comparison of the diametrically opposed points of viewLabels are a way of categorizing and organizing information.

In order to ensure that the product complies with all of the information provided, the solar panel quality inspection china inspection must include an examination of the product's operation as well as its unique characteristics.

Electrical measurements such as power, voltage, and current are taken place. Charge and discharge tests should be performed on the battery to ensure proper operation.

The test should be carried out with a high-potency liquid.

It is necessary to take your temperature.

Make sure there is no polarity in your design.

Test a solar-panel setup to ensure that everything works properly by connecting the inverter, solar charger, and batteries in the most comprehensive manner possible to ensure that everything works properly.

4. Verify that the logo, labeling, and markings are correct by inspecting them as follows:

Ensure that all barcodes are free of debris and that they are properly positioned in accordance with the manufacturer's guidelines.

The Production Monitoring of the logo, its colors, its size, its positioning, and its alignment are all important considerations to take into consideration.

Labeling and identifying:Check to see that the label contains accurate information and that it is properly marked before using it. Product labeling and marking: Product rating labels are checked and examined to ensure that they are accurate and that they comply with all applicable regulations and guidelines.

5. Inspect the packaging for any signs of wear and tear:

When inspecting the contents of a package, it is important to pay attention to the number of items and accessories that are contained within the package.

There has been adequate protection provided for the contents of the box in order to prevent any damage from occurring during the shipping process. It has been completed by placing the shipping marks and labels in the appropriate locations.

There is nothing wrong with the artwork on the retail packaging in any way.

It is critical that the appropriate printed literature is included in the package for use by the recipient.

In this article we'll take a look at the five most common problems that can occur when metal roofing is installed

When it comes to making the most cost-effective and environmentally friendly decision possible when purchasing a new roof, selecting the right type of roof for a new home is critical.

Typically, home owners simplify the situation to include the following elements:

Roofing materials such as asphalt shingles are used.

In the roofing industry, metal roofing refers to roofing that is constructed entirely of metal.

Consumers should be aware of a common problem with metal roofing before deciding on a metal roofing option. Consumers should be aware of this problem before making a purchase decision on metal roofing.

The most common problems with Oil Canning Metal Roofing are listed below, and they may have an impact on your final decision. The most common problem is issue #1, and it may have an impact on your ultimate decision.

According to the Metal Construction News, oil canning can occur when there is waviness in the flat areas of sheet metal panels on a metal roof, which is in the flat areas of the panels, and when there is waviness in the flat areas of the panels. Copper, zinc, aluminum, and steel are among the metals used in this type of fabrication, which is distinguished by the use of light-gauge and cold-formed metal materials, among other things.

A situation in which the standing seam of a metal system becomes overstressed and loses its ability to maintain its flat shape is illustrated in the following example:An advantage of purchasing a thicker metal is that it will last longer.

There are a variety of factors that influence oil canning, including but not limited to:

This configuration results in the metal being coiled to an extreme degree. There is a great deal of stress as a result of the coil cutting process.

This is the tension created by the roll forming of the panels on the assembly line.

In order to accommodate the expansion and contraction of the panels, there isn't enough space available.

During the installation process, there was a clerical error that occurred.

Friction is caused by structural changes that occur as a result of the movement of the panels.

(2) A leak has been discovered in the system.

With metal roofs, there are no exceptions to the rule of leaking roofs, which is a general rule. Having metal roofs increases the likelihood of experiencing leaks, which can occur for a variety of reasons, including human error or the nature of the material itself. The only other way to put it is that there isn't another way.

It is common for metal roof leaks to be caused by a variety of factors, the most common of which are as follows:

Winter weather includes things like ice melting and snow melting during the winter months, among other things.

It is predicted that there will be strong winds.

We can expect torrential rains and downpours, as well as structural damage to the house itself.

Although all of this is taken into consideration, installer errors are still the most common cause of leaks that originate from a metal roof system.

Inquire with your installer about the steps they are taking to avoid the Five Most Common Problems with metal roofing when it comes to leaks, and make sure you understand what they are doing. These are some examples:

Are the fasteners you're using the proper size and type for the job? Water can seep through screws if they are either too loose or too tight, or if they are not centered correctly on the screw heads.

Is it intended for the seams to be properly sealed in this case? Otherwise, leaks will begin to manifest themselves.

What type of butyl tape do you intend to use in your project and how much do you plan to use? Butyl tape will be used by the vast majority of metal roofing professionals, but they must make certain that they follow all applicable industry standards when installing the material. In the proper application, the tape will keep dirt and water out, thereby preventing any type of leakage.

The devil, as they say, is in the details. This is certainly true. It is possible that your roofing structure and the interior of your home will be harmed as a result of the work that is being done on them if you do not ask specific questions before proceeding. By inspecting their work, you can ensure that your installer is following the manufacturer's recommended installation guidelines.

Scratching and scuffing are common occurrences in this field. Even the most durable metal object, if not properly protected, is susceptible to scratches. Before hiring an installer, make certain that he or she has the necessary qualifications in the following areas.

In order to prevent the coating from being stripped off of the metal panels during the installation process, it is essential that they not be rubbed together during the process.

Furniture edge guards can be used to protect the furniture from being damaged.

An increase in the use of lifting devices is being implemented.

Rust and decay are the third and final elements that will be discussed in this section of the article.

A common source of reluctance to use metal roffing is the inevitable corrosion that occurs as a result of the process. This is one of the most common reasons for this reluctance. The fact that metal roofing is intended to be rust-resistant does not necessarily imply that it will be successful in doing so. This is due to a number of factors, including:

It is possible that rust has formed beneath the surface of the metal as a result of incorrect coating application.

Those locations where there is a high concentration of saltwater in the air.

Use of various metals in conjunction with one another is referred to as metallurgy.

This condition occurs whenever the edges of cut materials are not properly concealed or sealed, as is the case in most cases.

Metals and materials that are not related to one another are grouped together as type #4 materials.

When two different types of metals are used on the same roof, it is more likely that staining and failure will occur sooner rather than later. In the following situations, it is preferable not to come into contact with the metallic component:

The following materials are available as options for your project: treated lumber, concrete bricks, and copper.

The fifth type of error is one that occurs during the installation process.

Working in the shipping industry, it is common for materials to become misplaced after they have been received but before they can be shipped out to their destinations. Was there anything else that wasn't included with the delivery of the metal roof in that particular instance? Inquire with your installer about this, as it is an excellent question.

It is possible that your metal roof will not be properly installed as a result of the fact that installers do not want to spend the time necessary to wait for replacement parts. It's a shame, but it's a reality that must be faced.

There are some components of a typical metal roof that are absent.

Various accessories, such as screws and flashing, are included.

Typical metal roof components that are not present include screws, flashing, and other accessories, among other things. The best course of action to take in order to avoid the Five Most Common Problems with metal roofing is to avoid using metal roofing in the first place. If you find yourself in this situation, asphalt shingles are the most suitable option.

How to put on a hair wig that looks and feels like your own natural hair with nine tips

Wigs are an excellent option for those who have suffered from significant hair loss and do not wish to undergo a hair transplant or use hair growth techniques to remedy the situation. First and foremost, you should consider donning a wig to conceal your balding head of hair. Human hair wigs, on the other hand, are ideal for changing the color of your hair without the need to dye it, and they look absolutely stunning when worn in conjunction with your natural hair as well.

It is the most difficult part of the process to locate the best human hair wig that is currently available on the market today. This is due to the fact that there is such a wide variety of wigs available on the market today. Each company offers a distinct product or service that differs from the other in terms of both quality and price. It will be necessary to make a difficult decision regarding which one should be purchased in the first place. However, don't be concerned; in this article, I'll show you how to locate a hair wig that appears to be completely natural in appearance.

Hair products are available for purchase at hair salons and beauty supply stores, among other locations.

A wig from a costume shop or other retail establishment will almost certainly be prohibitively expensive. Furthermore, there is a scarcity of high-quality products on the market today, as well as a lack of variety in the marketplace. As a result, make certain that you purchase a hairpiece from an online or local hair store that appears to be natural-looking.

Select a wig that is made entirely of human hair whenever at all possible.

Currently, two types of wives are available: those made of artificial hair and those made of human hair. Artificial hair wigs are significantly less expensive than human hair wigs. When applied to the skin, it has a natural appearance and feels wonderful on the skin as well. When made of real hair, a wig can be styled in the same way that your own hair is, including blue-drying, ironing, and curling it in the same manner as your own hair.

A number of different human hair wig have been brought to your attention at some point, and you may be interested in purchasing one of them. The difference in price between Indian wigs and European wigs can be explained by the fact that the former are both more acceptable and less expensive, whereas the latter are both less acceptable and more expensive. Indian hair wigs are excellent choices when it comes to value for money because they are luxuriously soft and long-lasting. It's possible that you're not aware of any good deals on thick, straight hair at a reasonable price. Do you happen to know of any? Chines is a language that is widely spoken by a large number of people all over the world, including a significant number of people in the United States. A wig made of Chinese hair is the most cost-effective option currently available on the market.

In order to close the front of the dress, it has a lace-up closure.

In comparison to wearing a wig cap, wearing lace front or full lace wigs can give you a more natural-looking appearance. Given the fact that full lace wigs have significantly more layering than lace front wigs, they are significantly more expensive to purchase than their lace front counterparts. Aside from that, the lace front is less breathable and more irritating than the other options that are available. Large amounts of lace are the most flattering style for your body type, while delicate lace is less so.

A monofilament cap is included to provide additional comfort.

Despite the fact that it is expensive, the natural appearance of this wig more than justifies its cost. As a result of the hand tied cap, it is the softest, most lightweight, and most natural-looking of the bunch.

Right now, braided wigs are extremely popular among women.

In addition, headband wigs are the most natural-looking option for people who have little or damaged hair, or who want to experiment with different styles or colors, because they keep your scalp and hair healthy while still appearing natural and fashionable.

Obtain a wig in the same way you would if you were a woman.

If you don't already have a wig, you should think about investing in one and having it styled to suit your needs and preferences. The result will be a natural-looking wig that is an excellent match for your facial structure.

A thorough cleaning should be performed on a regular basis.

The longer you take good care of your wig, and the more often you brush it, the longer it will last you. It is recommended that you clean your wig with a normal shampoo every 6-8 wears in order to keep it looking new for an extended period of time. If you want to keep it safe from theft, don't leave it in plain sight or in the hands of curious eyes or hands. Because if you don't take good care of your wig, it will begin to fall apart sooner rather than later. Preserve your health to the best of your ability because you deserve to be well looked after. There are no monthly wig subscriptions available, and not all wigs are appropriate for all women and girls.

the selection of one random strand of hair at random

It is possible to achieve a more natural appearance by removing a few randomly placed strands from the hairlines of the head. Due to the fact that it is composed entirely of human hair, not only does the natural center of your wig provide a flawless appearance, but it is also exceptionally comfortable to wear.

To use the term toothbrush, you must be referring to a specific type of toothbrush that can be used.

Wigs become tangled and rough to the touch after a period of time due to a scarcity of natural oil sources in the environment. To finish detangling your wig, spray it with water and conditioner and then brush it with a wide toothbrush to remove any tangles that may have remained after you finished. It will assist you in keeping the condition of your wig in good condition.

colored wigs that have been dyed in a variety of shades

In the case of a blonde wig, you can easily tint and tone the hair to suit your specific needs. Natural hair wigs have a greater range of styling and coloring options than synthetic hair wigs, owing to the fact that they are made of real human hair and therefore have a more natural appearance.

An epilogue concludes the final act, which is followed by a coda.

By following the steps outlined above, it is possible to create a natural-looking hair wig that is also comfortable to wear. It is possible to procure a wig with relative ease; however, keeping it in good condition can be a difficult task to accomplish. The best one can do is complete each task to the best of one's ability. It is possible to have your wig for several years if you take good care of it and maintain proper storage conditions. If you want to appear fashionable and flawless, it is essential that you wear natural hair wigs and style them appropriately.

During the process of injection molding each cavity of a mold must have a small opening known as a gate in order for material to be injected into the cavity during the molding process

Injection ABS Injection Molding necessitates the use of a gate, which is a small opening in a mold that allows hot plastic to enter the cavity before passing through and around the internal features of the mold until the cavity is completely filled with plastic. Immediately after the part has been ejected from the mold, it is necessary to remove the sprue, runner, or small lump of plastic that has remained attached to the gate. In most cases, this is done by hand, and it is a time-consuming and challenging task. This may result in a faint vestige—also known as a witness mark—being left on the surface of the gate after installation, depending on the style of gate, the type of plastic used, and the geometry of the part.

Picking up any plastic injection molding part will reveal that the majority of gates leave a trace that is barely noticeable—assuming that the mold was designed properly, which is usually the case—and that this is true. Gates can and should be installed in areas that are not aesthetically pleasing as a first step, whenever it is practical to do so. When a gate must be installed in an inconvenient location or when the raw material necessitates a gate that is larger than average in size (for example, glass-filled resins), it is possible to reduce the unsightly factor.

Moldplasticinjection employs three different styles of gates during its plastic injection injection blow mold manufacturer operations, and this design tip explains how to use each of these gates to produce aesthetically pleasing and cost-effective molded parts in the shortest amount of time possible.

The tab gate is the type of gate that is most frequently encountered

If we're talking about gates, the tab gate is the most commonly used (and largest) type on the market today. When you examine the part without trimming it, the gate will appear as a tapered rectangle protruding from the outer surface of the part. When possible, it is placed where the part is thickest and always at the parting line, where it is relatively easy to trim and has the least impact on the overall appearance and function of the part.

In contrast the use of wigs has recently emerged as a fashion trend as demonstrated by the recent wig modeling show that took place in New York City earlier this month which was attended by celebrities and fashion designers

As a result of the fact that many female celebrities in Europe and America, including Paris Hilton and Britney Spears, are well-known for their fondness for wearing wigs, one of the next topics on the agenda for discussion is how to keep wigs on women's heads shining indefinitely, which is a positive development.

The art of making wigs is our specialty, and we will teach you everything you need to know so that you can become an expert in this field on your own.

No matter how large or small their wig collection may be at any given time, most makeup artists will always have a variety of cosmetics and make-up options on hand when it comes to cosmetics and make-up applications. This is true for both wigs and makeup. According to this, the desire for changeable shapes in one's consciousness increases in intensity with each passing generation, which is an extremely compelling argument. According to the report, people who are living in their own homes have reported having problems with their wigs. You must bring them back to you on a regular basis if they have been left alone for an extended period of time to keep them happy and entertained. You have no choice but to discard them because they are no longer of any use to you. While wives are significantly more expensive than toilet paper, they represent an outright waste of money in terms of financial resources when compared to toilet paper. In contrast, wigs are a little harder to come by these days. When it comes to Bobo Wigs , it is essential that they are permanently shiny and shaped to look like real hair vendors list in order for them to be free of the need to be cleaned after each and every use. The time and effort it takes to clean our wigs every time we put them on or take them off will be saved as a result of this method of doing things.

Demonstrate how to choose the highest-quality wig available on the market at the time of your interview by providing an example.

It is true that there are many different types of wig products on the market, but the quality of these products varies greatly. On the first occasion that you wear a wig it is possible that you will be mistaken for having fake hair on; this is not an uncommon occurrence when wigs are worn for the first time. The fact that different people will be looking at your shape from different perspectives can be extremely embarrassing for you in this situation. Instead, you can become familiar with the procedure for selecting the most appropriate hairpiece for your specific situation by reading about it.

Wigs made of artificial fiber, wigs made of human Wholesale Peruvian Hair Bundles (including synthetic fiber), and wigs made of genuine human hair vendors (which may include real hair) are the three types of wigs currently available on the market. Wives made of synthetic fibers are the most common type of wig found on the market today.

It is possible to manufacture chemical fibers in the following ways, and they are widely used in a variety of applications:It is also advantageous in that it is inexpensive and that the desired effect is created in an artificial environment. If you are a video game player who is participating in Cosplay or a model appearing on a runway show, you are permitted to wear a wig of this nature in real life. However, it is not permitted to do so in any other situation.

The cost of real hair is higher than the cost of synthetic hair, despite the fact that real Wholesale Indian Hair Bundles is more frequently used in film and television dramas than synthetic hair. Another reason real hair is more commonly used in films and television dramas is because it is more realistic.

After conducting three studies, researchers determined that a wig made of chemical fiber and human hair is the most appropriate wig for life. However, it is prohibitively expensive, costing more than $30 per wig. Choosing to wear this wig raises the possibility that others will mistake it for the real thing, which is a very serious situation to find yourself in.

Take into consideration that the net material that was used in the wig's construction is the first and most important factor to consider when building the wig.

When choosing a wig, the comfort and permeability of the mesh should be the first and most important considerations to make, just as they should be the first and most important considerations to make when choosing a lace front wigs, as they should be the first and most important considerations to make when choosing a wig. After applying the product, wait a few minutes before examining the skin for signs of itching or irritation once more. Tucking the elastic band inside the wig will assist you in keeping it in place throughout the day and ensuring that you receive the most accurate results available. If you have an athletic body type, look for clothing that is neither too baggy nor too tight on your body and around your waist; otherwise, you will appear sloppy. The importance of keeping in mind that the wig should become a little looser with wear over time, but not too loose at the same time, in order to avoid giving the appearance of being untidy, cannot be overstated. It is always preferable, unless there are exceptional circumstances, to make it to order whenever possible in the event of a time constraint.

Before proceeding with the rest of the procedure, you should first burn and blow-dry your hair to determine the general condition of your hair.

Afterwards, the texture of your wig vendors should be considered in the subsequent stage. As a general rule, it is believed that when poor-quality hair is burned in the presence of flames, an offensive odor is released into the air during the burning process. Interestingly, the combustion process lends credence to this belief. It is recommended that you use a hair dryer set to the highest heat setting for 3–5 seconds in order to avoid permanent damage to the mesh material. However, you must be careful not to hold the air outlet open for an excessive amount of time, or the mesh material will be permanently damaged. As long as the hair is genuine, there will be no problems with the procedure. As a result of the use of other materials, the horse's feet will become exposed, and as a result of this exposure, the horse will emit an odor.

As previously stated, the third step entails selecting a hairpiece that is complementary to your skin tone and hair coloration in order to achieve your best appearance.

According to conventional wisdom, wives' faces should be painted in a way that is complementary to the wearer's skin tone to ensure that they look beautiful. Consider selecting a lipstick shade that is the same or similar to the color of your hair, if you have one, in order to ensure that your outfit is well-coordinated. In order to avoid appearing unnatural, it is critical that your makeup matches your skin tone as closely as possible, regardless of whether you have a lot of hair or no hair at all. When choosing wigs for people with white skin, look for shades of brown yellow or light brown; when choosing wigs for people with black skin, look for shades of chestnut or dark brown; and when choosing wigs for people with yellow skin, look for shades of red. When choosing wigs for people with white skin, look for shades of brown yellow or light brown. When planning these types of gatherings, think about the color and light of your makeup to ensure that you are prepared for make-up parties. When planning these types of gatherings, makeup colors can range from wine red to yellow to orange red to purple red, among other shades, depending on the occasion. Because of the length of the event, it is recommended that the wig be as long as possible.

To achieve their goals of being on the cutting edge of fashion and looking their best, women and men alike are increasingly turning to the use of wigs to accomplish their objectives. As new generations of people who wear wigs enter the picture, the textures of the wigs become more realistic and humanized in appearance, and the cycle is repeated. Wigs are popular among female celebrities in both Europe and the United States, with celebrities such as Paris Hilton and Britney Spears, to name a few, expressing their preference for the style of hair factory wholesale in question. We make certain that wigs are delivered on time and in a location that is convenient for the customer to receive them. In the following section, you will find detailed instructions on how to extend the life of your wig, as well as how to clean and maintain it.

It will be necessary to have the wig professionally cleaned after it has been worn for extended periods of time in order to maintain its appearance and maintain its shape.

Running your fingers through the wig smoothly before starting the wash cycle allows you to make any final preparations for washing that are necessary before beginning the cycle.

Washing wigs in warm water (approximately 20 degrees Celsius) with an appropriate amount of moisturizer shampoo is recommended before soaking in the water for 5 minutes, gently brushing it clean, and rinsing it thoroughly with fresh water to remove any remaining product.

The following steps include thoroughly mixing a sufficient amount of conditioner into a bowl of warm water and allowing it to sit for 10 minutes, soaking the wig in the water, and thoroughly rinsing it4. After gently tapping or shaking the best wholesale virgin hair suppliers to remove any excess water, comb it as naturally as possible before storing it in a well-ventilated area to allow it to air dry completely.

Always make sure to allow the hair on your new wig to dry completely before styling it into a fashionable hairstyle to complete the look before wearing it.

In order to develop an open mindset and a collaborative mentality it is critical to lay a solid foundation on which to build

It is possible to be confident that you are working with true professionals on your project if your integrator provides detailed drawings of each phase of Storage And Retrieval transformation and has prepared contingency plans in conveyor event that they encounter unforeseen issues.

The members of the team should put together a presentation on the proposed strategy for putting the project into action as soon as possible. Please don't be afraid to request documentation from your integrator demonstrating the qualifications of automated storage installation subcontractors they intend to hire for your project. At a time when your company is experiencing a high volume of activity, you don't want inexperienced installers working on your system. In order to ensure that any modifications made to your system are tested thoroughly before Storage And Retrieval system is expected to be put back into live operation, make sure that adequate time has been set aside for this purpose.

A common occurrence is the involvement of a warehouse management system (WMS) or enterprise resource planning (ERP) in a project in which the client's automated warehouse or manufacturing process is communicated with. To ensure the success of your project, it is critical that you designate a single point of contact on your project team who will be available to answer questions in motor assembly lines & conveyors event that an interface between your WMS/ERP and Conveyor belt automated solution is required. As a result, your WMS/ERP expert will be able to collaborate with your integrator on interface communication testing in order to prepare for the switchover while you are waiting for the cutover to occur. The result of this arrangement is that debugging efforts between software experts on conveyor client's side and those on the integrator's team can be more efficiently coordinated and expedited.

Approximately $7 billion is expected to be generated by 2021 in the United States; approximately $6 billion is expected to be generated by 2026 in China according to projections

According to industry projections, the sheet metal fabrication services market in the United States will grow from its current level of US$1.3 billion to US$2.7 billion by 2021, from which it is expected to grow by a factor of two. As of the time of this article's publication, it is estimated that the country has a 17.78% share in the total global market revenue. It is predicted that China's market will grow at a compound annual growth rate (CAGR) of 3.4% over the course of the study's five-year duration, reaching US$6 billion in 2026. China is the world's second-largest economy. Japan and Canada are two other noteworthy geographic markets to consider, in addition to the United States and Canada, when expanding your business. These markets are expected to grow at rates of approximately 1.5% and 2% per year, respectively, over the course of the research period.

According to projections, the German economy is expected to grow at a compound annual growth rate of approximately 1.8% over the next five years, based on projected growth rates, according to estimates. By 2027, revenues in the rest of Europe (as defined in the study) are expected to reach US$6.2 billion, according to the study. In North America, the growth of the sheet metal fabrication market is being fueled by an increase in construction projects, as well as the region's strong aviation and defense industries, among other factors. In the Asia-Pacific region, it is believed that the availability of readily available raw materials and the region's relatively low labor costs have both contributed to the region's rapid growth in the manufacturing industry over the past few decades.

According to a recent report, companies are increasingly relocating their manufacturing operations to Asia-Pacific regions in response to an increase in demand for services in the region. As a result, the demand for services in the region is increasing at a faster rate than previously.

By 2026, the Bend Sheet (Form) segment is expected to generate $5.7 billion in revenue, a 14% increase over the current year.

As a result of the fact that bend sheet is widely utilized across a variety of industries such as manufacturing, automobile construction, electronic and telecommunications, among others; this has aided in the growth and development of this segment. In this segment, the rapid urbanization trend that is taking place all over the world, as well as the increase in construction activities that has resulted as a result of this trend, are both considered to be positive indicators. is becoming more efficient and straightforward as automation becomes more prevalent in the industry. This is especially true for the process of bending and cutting sheet metal fabrication. On a global scale, the United States, Canada, Japan, China, and Europe are expected to drive demand for Bend Sheet (Form) for a significant portion of the forecast period. It is anticipated that the global Bend Sheet (Form) market will grow at a compound annual growth rate (CAGR) of 2.6% over the forecast period.

This is expected to result in an increase in the combined market size of these regional markets, which is estimated to be US$3.9 billion in the year 2020, and to reach a projected market size of US$4.8 billion by the end of the analysis period, from a projected market size of US$3.9 billion in the year 2020. China is expected to maintain its position as one of the fastest growing markets in this group of regional markets in the foreseeable future, despite the fact that it is already one of the fastest growing markets. However, the market in Latin America is expected to grow at a compound annual growth rate (CAGR) of 3.2% over the course of the investigation compared to the market in Asia-Pacific, which is expected to reach US$570.5 Million by 2026 (with countries such as Australia, India, and South Korea leading this growth).

A number of advantages can be gained by using customized chocolate boxes

Other considerations include the level of customization available in terms of printing, which is another important factor to consider. A diverse selection of custom custom chocolate box boxes is used to achieve this personalization, which encourages customers to become long-term patrons of the company. These printed Chocolate Boxes boxes are created by the manufacturers using a variety of printing techniques, which helps to ensure that the printed material remains on the boxes throughout the manufacturing process. Examples of effective and well-known techniques include graphic and screen printing, which are among the most effective and well-known techniques today. Color palettes such as CMYK and PMS are also being used for color schemes because RGB is now considered obsolete and the former produces significantly better results on custom box packaging than the latter. Furthermore, depending on the event or the needs of the customers, a wide range of printing options are available to suit their requirements.

Personalization in accordance with the occasion or holidays

This is true; these Chocolate Boxes have a strong ability to be customized, which is why they are extremely popular. chocolate packaging is a delicacy that is enjoyed by people of all ages, which means that these chocolate box packaging boxes can be customized for people of all ages and events. Furthermore, through the use of customizations, it is possible to target a specific group of people with relative ease. Preserved chocolate box packaging is the source of this sweet and alluring delight, and custom truffle boxes are an excellent way to incorporate it into celebrations and festivals such as birthdays, Christmas, and wedding favors, among other things. Simply by the magic of custom chocolate boxes boxes, you are compelled to bring adorable little chunks of chocolate pieces to your special events, which is exactly what you should do. For children, these boxes can be customized to include their favorite cartoon or superhero characters, which will make your target audience happy and excited about receiving these boxes. Aside from that, they are exquisitely designed to be used as favor or gift boxes for special occasions. This will be exchanged for the ability to request a variety of additional items to be included in these boxes. There are a variety of options available, such as organza ribbons, baker's twine, and various die cut designs, such as petal or bow tie tops, among others.

Color scheme selection, as well as logo design, are important considerations

Another way to make use of these printed chocolate boxes is to use them as a marketing medium. To begin, simply choose the printing technique and color palette from the list above that you believe will be the most effective for your needs. In addition to the printing, these chocolate boxes are personalized with the company logo and a clever color combination to make your Custom Box Packaging stand out from the competition. In addition, information such as the company name, address, any web page addresses, and even barcodes can be printed on the label to identify the product or service. Your customers will remember you as a result of the extensive information you have provided.

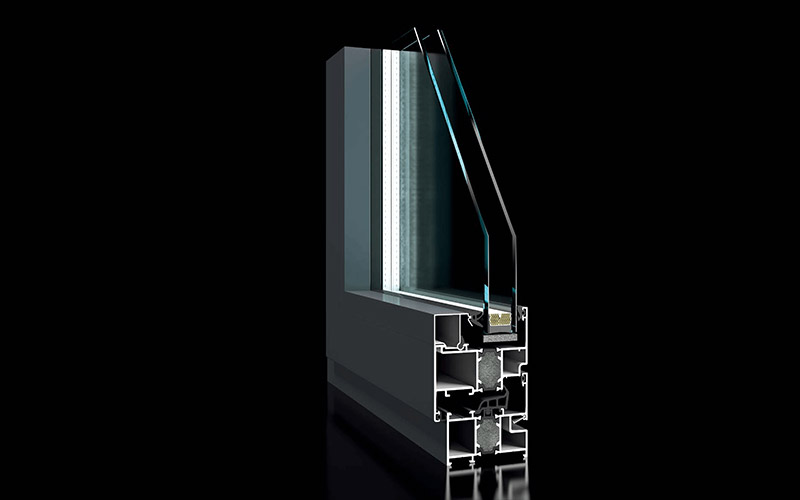

Dow plans a program to use carbon-neutral silicones in the construction of building facades

Dow plans to launch the world's first commercially available carbon-neutrality program for silicone materials used in structural glazing, insulating glass, and weathersealing in 2022, with the goal of becoming carbon-neutral by 2025. The carbon certificates from Dow's backward integrated siloxane productions and carbon reduction investments will be included in the selected DOWSILTM Materials, which will be PAS 2060-certified. It is hoped that this carbon offset program, with its theme of "Designing with more freedom by engineering less impact," will assist in reducing the environmental impact of buildings and achieving higher green building certification ratings.

It is estimated that the building sector is responsible for approximately 39 percent of global CO2 emissions, according to the World Green Building Council. This includes both embodied carbon and carbon dioxide emissions from building operations. However, while the production of Dow's silicon products requires energy, the use of these products in applications such as prefabricated façade elements and glass insulation requires very little energy, thereby contributing to a significant improvement in the overall energy efficiency of buildings. Furthermore, because of their proven durability, the insulated building envelope can be expected to last for more than 50 years. According to the Global Silicones Council, the energy to carbon ratio of silicone sealants conserves up to 20 times more energy than the energy required to manufacture them for insulated glass.

Carbon-neutral silicones have the potential to reduce to zero the amount of carbon that is required to manufacture the silicone polymers that serve as the building blocks of our products. Carbon-neutral silicones for low e insulated glass specific building projects represent a ground-breaking innovation, particularly for technologies associated with the silicon metal manufacturing process, in which Dow is uniquely positioned.

In the field of building and construction, Plettau is confident that silicone will continue to be the technology of choice, not only because of its long-term performance and low carbon footprint, but also because it equips buildings insulating glass with improved energy and greenhouse gas emissions performances.

It is also a key to achieving significant ongoing carbon reduction through integrated design solutions, which allows these industry professionals to design with more freedom while engineering less impact," said Plettau. "The carbon-neutrality program for DOWSIL Silicone materials is not only an advantage for architects, builders, and building owners, but it is also a key to achieving significant ongoing carbon reduction through integrated design solutions," said Plettau.

As a result of their PAS 2060 certification, which is an internationally recognized standard for organizational carbon-neutrality, Dow's carbon-neutral silicones will be able to contribute to the achievement of additional international green building certification points. Each product will be equipped with an Environmental Product Declaration (EPD), which will communicate transparent and comparable information about the environmental impact of our products throughout their life cycle.

The function of low-emissivity glass is not well understood

When researching your window and replacement window options, you may come across the terms 'Low-E glass' and 'Low-E coatings,' which refer to low-emissivity glass and low-emissivity coatings, respectively. These terms may appear quite frequently in the literature. The term "window technology" is becoming increasingly popular, but many people are still unsure of what it actually means in this context. It's not entirely clear what it's intended to be used for. In addition, how does it differ from the various other types of coatings that are currently available, such as solar film?

In what way does Low-E glass perform its functions, and how does it achieve these results?

Low-E glass is a type of glass that has a low emissivity (or reflectivity), which means it is less reflective than other types of glass. The coating, in addition to blocking out a significant portion of ultraviolet and infrared light, can also allow the vast majority of visible light to pass through without causing any degradation in clarity. To protect your home from the effects of ultraviolet (UV) and infrared (IR) radiation, low e insulated glass is necessary to take the precautions listed below. UV and IR radiation can cause the following effects:

In addition to its role in the development of skin cancer, which is certainly a legitimate reason to exercise caution when exposed, ultraviolet light is also known for its role in the development of other types of cancer, including lung cancer. But this does not represent the full extent of the harm that it is capable of causing. It is important to note thatAside from that, if certain materials are exposed to the sun for an extended period of time, it is possible that the color of the materials will start to fade.

It has already been stated that infrared light is closely associated with heat energy; in fact, infrared light is responsible for the vast majority of the heat that you experience when exposed to the sun. Infrared light and heat have a complicated relationship, and it is important to understand that controlling IR light improves your ability to control the passage of heat through your windows.

What exactly is the purpose of Low-E glass? Can you tell me more about it?

Low-E (low-emissivity) coatings are used to block out the vast majority of ultraviolet and infrared wavelengths of light while still allowing the vast majority of visible light to pass through the window when applied to windows. They differ from one another in terms of manufacturing and application processes when compared to something like a solar film, which has the following characteristics:A Low-E coating is a thin layer of material that is applied to a product during the initial manufacturing process to protect it from the effects of the environment. The fact that it has such a strong bond to the glass makes it unlikely that you will even notice it is there. Consider the fact that you will not be able to apply the Low-E coating to your windows after they have been purchased and installed when making your decision on which windows to purchase. In order to achieve the desired results when installing Low-E windows, it is first necessary to purchase Low-E windows, which can be found here. In addition, because the coating has been applied by the manufacturer, there is no risk of the coating voiding your warranty, which is something to be concerned about when using solar film.